Per meliorem efficientiam et productivity de productio logistics ratio,Non possumus consequi maior beneficia in praemissa reducendo productio cost. Licet output de cylindro potest augendis augendae in labore et acquirendi novum apparatu, productio capacitatem existentium cylindro productio linea non dimisit ad maximam partem, et operatio productionem linea est humilis.

Quod "Takt" de productio processus est tempus inter duo successivus complementum eiusdem uber (vel duos servings).In aliis verbis, in mediocris tempus capit ad perficere a uber. Cycle tempus solet solebat definias unitas output tempus a propria processus vel gradus in processus. Si productum factum est in batches, in cycle tempus est intervallum inter duo batches products. Processus consilio, si processus datur output quod debet produci quotidie primum quod necessitates considerari tempo processus.

Processus vel link cum tardissime exolvuntur tempore in productio processus plerumque referred to as "bottleneck". Bottlenecks in productio processus non solum limit altiore output celeritate unius processus, sed etiam afficiunt productio facultatem alia links. More broadly, the so-called bottleneck refers to the various factors that limit the output of the entire process, such as: raw materials cannot be in place in time, information flow is blocked, manpower is insufficient, equipment failure, etc. Bottlenecks can also "drift" depending on the product produced or the manpower or equipment used in a specific period of time."Line balancing" refers to equalizing all processes of production Et adjusting opus onus ut opus tempus cuiusque processus quod proxime.

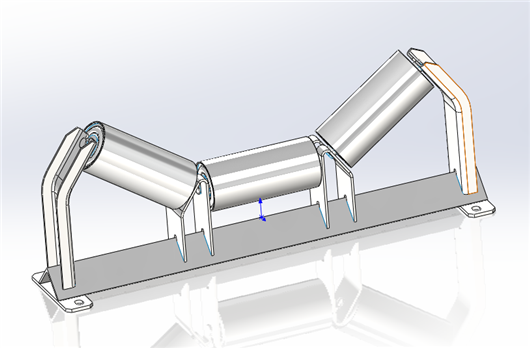

Pelagus ad statera analysis de cylindro productio linea est:ad brevi processus et vestibulum tempus unius cylindro et amplio altiore efficientiam de cylindro productio linea; Rationabile Ordinatio rudis materiae, reducere ad praeparationem inter processibus, amplio tempus utendo, et efficaciter reducere logistics costs; Reduce the work-in-progress inventory of rollers, improve the strain capacity of roller production in the workshop, etc. By analyzing the balance rate of the existing production line, the problems and deficiencies of the production line are clarified, so as to reasonably design the production line, maximize the production capacity of the production line as much as possible, and improve the efficiency.